Interview: How Touchscreen Computers by faytech® enable Shop Floor Management in Harsh Production Environments

FAYTECH

Mr. Kesper, your company uses touch devices by faytech® brand as the hardware basis for your shop floor man-agement software solutions. First of all, what is that? It may not be familiar to everyone who doesn’t work in industry.

Kesper:

In small and medium-sized companies, visitor badges being issued manually at reception, and employees in the common rooms being informed of visitors via whiteboards. In the production area, good and bad parts being recorded on physical tally sheets, and requests for material being written down on paper, which someone then carries from A to B. It’s 2025, and in many places what I’ve just described is still part of everyday life. At LEANIO, we are the people who help everyone become more digital. And your touchscreen computers are helping us.

FAYTECH:

Can you describe this?

Kesper:

We work with software developed in-house. We adapt it to the use cases and specific challenges that each customer has in their production or logistics areas. Our programs are so flexible that the effort involved is usually very manageable. Sometimes it only takes a week for us to hang the first faytech® touchscreen computers on the wall or on a machine and for the software to go live.

Dr. Björn Kesper, born in 1971, is Managing Director of LEANIO GmbH. Before that, this PhD in computer science worked as a research assistant at technical universities and as an IT manager in industry. Kesper and LEANIO are dedicated to the digitalization of small and medium-sized companies with software developed inhouse. The main focus is on shop floor management in production and logistics. If desired, LEANIO can also include the company‘s administration in the solution concepts. Pyramid supports LEANIO GmbH as a hardware provider, with faytech® brand touchscreen computers and digital signage. Björn Kesper has been relying on these not just since LEANIO GmbH was founded. Find out in this success story why Björn Kesper has trusted faytech® for many years, and what benefits faytech® offers his customers.

FAYTECH:

When did you begin using faytech®?

Kesper:

Before becoming self-employed, I was the IT manager of a company. That‘s where I started working on shop floor applications. When we first started out, we opted for commercially available Windows-based tablets, i.e., consumer products. We quickly learned that the tablets were good, but not at all suitable for our demanding industrial environment. In my search for a touch monitor or touchscreen computer for harsh environments, I came across faytech®. So, basically, I started purchasing from you about 15 or 20 years ago. Your hardware has accompanied me throughout my professional career, right up to self-employment.

FAYTECH:

We‘re so glad to hear this! Why us and not someone else?

Kesper:

You have a broad portfolio. I can get touchscreen computers and touch monitors from 7“ to 21.5“ from you, and even up to 32“ if I needed them. There is a broad range, from aluminum-framed systems for undemanding office environments to rubber-framed and openframe systems that I can use in very harsh industrial environments. You also have digital signage, which I can use for entrance areas or break rooms if a customer wants a digital solution there, too. For example, a 65“ info panel instead of a whiteboard. Another reason is that your hardware is always up-todate. The touchscreen computers I received last year already include Intel‘s Elkhart Lake technology. For me and my customers, this means performance, future-proof products, and therefore a long return on investment.

But for us, the most important factor is reliability and robustness. Customers often tell us in the initial meeting: „It‘s dirty here. If dust gets into these systems, or if someone really bumps into something while working, it‘s all going to break.“ In these cases, I reply that LEANIO definitely has customers whose production facilities are much dirtier. Then I say: „No need to worry. Trust us. We have the right hardware for you.“ Of course, even a faytech® panel sometimes fails after a while under extreme conditions.

But that‘s just what happens in harsh to very harsh environments. From my point of view, your hardware has by far the best price-to-performance ratio – I mean, worldwide. Especially for small and medium-sized companies, it‘s important that one panel doesn‘t cost €5,000, but much less.

FAYTECH:

Which customers do you have in mind when you talk about dirty production environments?

Kesper:

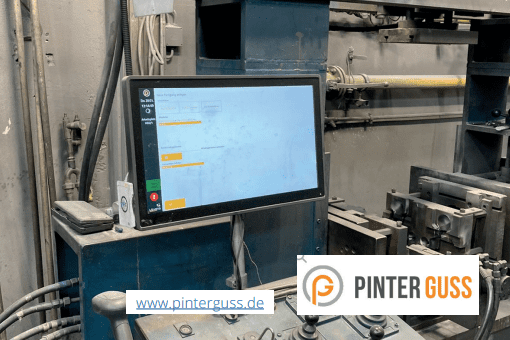

One of our customers is an automotive supplier who manufactures carbon parts for Bugatti, among others. In the summer, it gets so hot in their halls that every consumer tablet will fail. We set them up with 10.1“ touchscreen computers from faytech®. We‘ve also installed your touchscreen computers in CNC operations, which means milling and turning. Iron filings flying everywhere, long shavings, short shavings, everything you can think of, and every now and then a splash of coolant. And things are really rough in a foundry that we take care of. They handle heated aluminum there, there‘s steam and smoke. In one department, the air is very dusty, because the liquid material is poured into molds made of sand. And in the middle of all of this are your systems.

FAYTECH

We‘ve talked about the qualitative and technical benefits that faytech® solutions have for you and your customers. We started our conversation with the benefits of digitalization in production in small to medium-sized companies. It would be great if you could finish by explaining some of the use cases for which LEANIO uses our hardware.

Kesper:

With pleasure! We deploy your touchscreen computers to bring data to where they are needed: the machine. The operator can see what and how much to produce on the display. If desired, we can display detailed assembly instructions on the full-HD touchscreen. And, of course, we send the work results from the touchscreen computer directly to the ERP. The worker simply taps on the screen to record which part is good and which is bad. Gone are the days when the production prep team walked around the factory handing out order slips and in turn collecting tally sheets with the results, and then manually typing them into the ERP. This is just one example of the digitalization we can achieve in production. Digitalization means enormous time and cost savings, and an overview of benchmark figures down to the second. Let me also add that digitalization with LEANIO software and faytech® hardware is not limited to production. We have digitized the order picking process for one of our customers. Until recently, the shipping carton came down the conveyor belt to the employees with a packing slip. The slip of paper stated which kinds of muesli the customer wanted. However, their product range is very extensive, and the pictures on the cans on the large storage shelves often look very similar. Under time pressure, the slip-of-paper-process was prone to errors, and as a result, up to 200 packages were packed incorrectly each day.

FAYTECH

Dear Mr. Kesper, thank you very much for your time and for this informative and pleasant conversation.

Kesper:

Any time, with pleasure. Looking forward to continued good collaboration in the future!

Get Personalized Touchscreen Expertise Today

Ready to transform your vision into reality? Schedule your personalized, no-obligation consultation with a Faytech North America touchscreen expert. Discover tailored touch solutions proven to drive success across diverse industries, and learn exactly how faytech can elevate your next project.